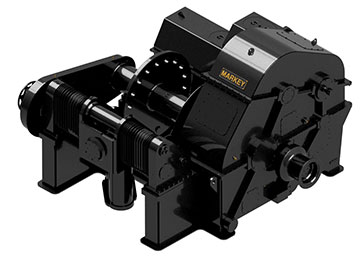

High Performance Markey Render/Recover® Winch Systems

In the late 1990’s Markey Machinery began working with customers to develop an ultra-high-performance winch system. This new winch system (Class II & Class III ARR), designed specifically for workboats & tugboats, now had the capability of making use of a workboat’s full horsepower and capabilities with more emphasis on safety for the crew, vessel, and environment. This system is continually being improved upon with every order; ever-evolving into a highly-advanced system that can readily be adapted to multiple applications and missions based on the changing needs of the customer. Such remarkable advances in these workboat equipment features and capabilities have transferred well to the applications and needs of oceanographic research work, allowing for more dependable data gathering and also reducing the risk and costs associated with the loss or damage to scientific research equipment.

Markey hawser escort winches and ship-assist winches utilize superior technology and capabilities through their Render/Recover® or Asymmetric Render/Recover® (ARR) technologies. Render/Recover® is a dynamic constant-tension winch control system that provides equal power for both inhaul and payout of hawser line. Functionally, one can think of it as a spring-loaded dog leash. Asymmetric Render/Recover® in conjunction with a water-cooled disc brake, is the same thing, but with much higher power capability on the payout side of the cycle and are therefore considered a “super winch.”

Markey Render/Recover® – History & Evolution

Traditionally, and to some extent still today, ship assist lines were worked by hand. Eventually the size and horsepower of tugboats increased to the point where a line with adequate strength became too heavy for a man to handle (about 3” in radius). To meet the demand for stronger lines in smaller sizes, a new type of rope was developed, referred to as Ultra High Molecular Weight Polyethylene or UHMPE synthetic line. (It is interesting to note that a 3” manila line with a breaking strength of 38 tons can today be replaced with a Spectra line of the same diameter with a breaking strength of 427 tons.) It is now considered impractical to handle lines of any size on a tug over 3000 horsepower by hand because of crew safety, operating costs, and the ability to respond quickly to any ship-assist or escort situation. These are all factors that are considered critical to a tugboat’s operation.

Development of the Render-Recover® Winch System

In 1995, with the construction of the tugs Protector and Guard for Crowley Marine Services, Markey Machinery developed the operational concept of Render/Recover® controls for its hawser winches. The idea was to develop a winch that would increase the performance, speed, and safety of certain tug escort and assist operations by automating certain winch functions. The primary goals were based on controlling line tension to:

- automatically haul in and pay out line during close-in ship-assist maneuvers,

- automatically haul in and pay out line during extended escort operations (in some cases, tanker escorts had a duration of over 10-12 hours) to reduce operator fatigue and wear and tear on the hawser line.

The Class II Hawser Winch with the Render/Recover® system provided automatic “constant-tension” performance up to the limit of the hydraulic or electric power available, generally less than 75 to 100 horsepower. These power limitations of the first Class II Hawser Winch’s led to the development of the CLASS III Escort Winch with Markey Asymmetric Render/Recover® controls.

Increasing Render-Recover® Performance & Speed

Early in 2000, Markey Machinery was asked to develop a winch concept for Crowley’s planned new tug, the Response. This tugboat would be involved in high-speed tanker escorts in the Strait of Juan De Fuca and ship-assist operations in Anacortes, Washington. Design goals for this new concept included:

- Increasing Render-Recover® performance to match indirect towing requirements by increasing inhaul and payout line-pull to as much as 250% of the tugboat’s bollard-pull,

- Increasing the Render/Recover® inhaul and payout speeds from 20% (250 ft/min.) of the tugboat’s free-running speed to 50% or more (to over 600 ft/min.)

The solution was to design a three-speed gearbox, or transmission, below-deck, controlled by a programmable logic controller (PLC) to automatically shift between ranges as required to match pull and speed requirements. As well, the overall system efficiency and performance was increased by using Alternating Current Variable Frequency (ACVF) electric power to drive the winch. Electric winches offer the highest overall system efficiency, providing full programmability and the ability to dissipate horsepower through dynamic braking resistors. Another feature of the new design was a wheelhouse adjustable levelwind that allowed the operator to influence how the line is spooled onto the drum. Synthetic hawsers are difficult to spool at high load due to problems associated with “diving” or “burying the line.” The approach taken was to set up the levelwind for open-weave type spooling and give the operator the ability to increase or decrease the spooling speed from the wheelhouse. This helps avoid issues while on missions and in full force maneuvers.

Improved Shock-Load & Braking Control

Finally, a water-cooled multi-disc brake was integrated into the design to improve shock-load and braking control, eliminating the drawbacks of traditional band-type drum brakes. Self-energizing band-type brakes are known for being able to withstand very high loads but they cannot be made to “slip” in a reliable, smooth fashion. Caliper-type disc brakes were ruled out for this application due to the marine environment and design considerations. The water-cooled multi-disc brake was mounted to the below-deck portion of the winch gearbox and provides finely controllable braking (or “rendering”) at up to 3x tug bollard-pull and handles payout speeds at up to 15 knots. With the water-cooling feature, this brake can dissipate a total of up to 1600 HP continuously.

Asymmetric Render/Recover® – History and Evolution

Existing Hawser Tension Displays are limited to displaying line tension only when the drum band brake is set. With Markey Asymmetric Render/Recover® Controls, a strain-gauge type load pin is incorporated into the gearbox on an idler-pinion that can continuously and directly measure drive and braking torque. This is displayed in the wheelhouse as line pull. To simplify use, the engineers at Markey Machinery improved operator controls in the wheelhouse by separating them into “primary” controls on the starboard side and “secondary” controls on the port side.

The weight of this winch was a major concern. The challenge was to achieve a balance between minimum weight while also making it strong enough to react to operational loads. The finished weight of an ARR Winch ranges from 25 to 60 tons.

Asymmetric Render/Recover® Enhancements

Since the original ARR winch project, many variations of this winch design have been developed to adapt to the vessel and performance requirements of our individual customers. To date, winch power ranges from 100 horsepower to 800 horsepower have been developed and implemented. This marine deck equipment is relied upon to perform daily tanker and LNG carrier escort missions in ports in the US, Canada, Mexico and Australia. Recent advances in network communications allow remote access into winch control systems for the purpose of tuning and troubleshooting, vastly increasing Markey’s ability to respond to their customer’s needs.